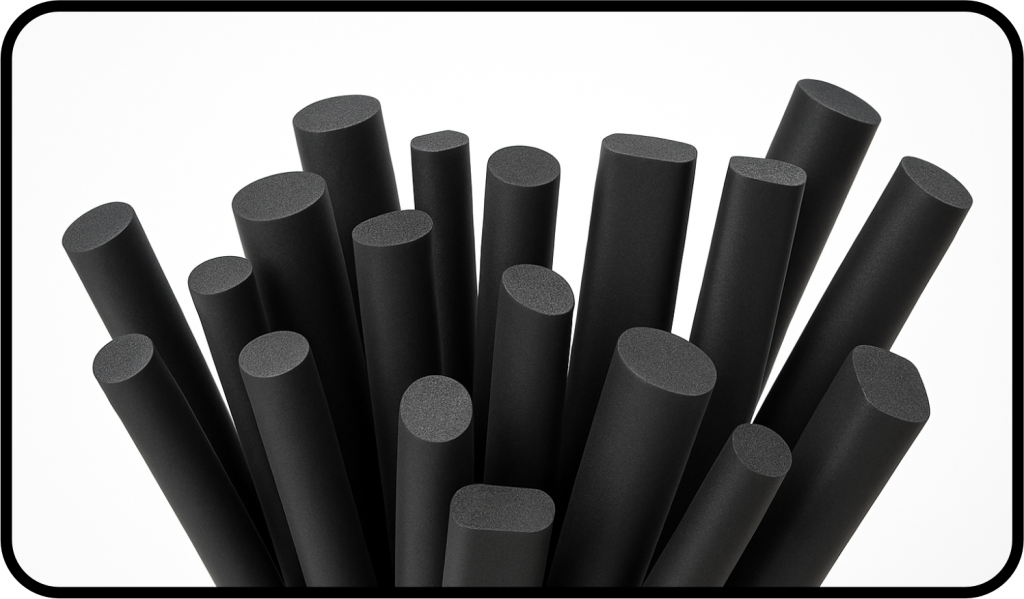

Sponge rubber, also known as foam rubber or cellular rubber, is a type of rubber material that has a porous, sponge-like structure.

Here are the key details about sponge rubber:

Composition: Sponge rubber is typically made from natural or synthetic rubber compounds that are mixed with various additives such as blowing agents, curing agents, and fillers.

Manufacturing Process: The manufacturing process involves mixing the rubber compound with the additives and then subjecting it to heat and pressure in a mold. During this process, blowing agents release gases, creating bubbles within the rubber matrix, resulting in the sponge-like structure.

Properties:

Porosity: Sponge rubber is characterized by its open-cell or closed-cell structure, which gives it its sponge-like appearance. Open-cell sponge rubber has interconnected voids, while closed-cell sponge rubber has sealed cells.

Softness and Compressibility: Sponge rubber is soft, flexible, and compressible, making it ideal for applications where cushioning and shock absorption are required.

Water and Air Resistance: Closed-cell sponge rubber exhibits good resistance to water and air penetration due to its closed-cell structure.

Thermal and Chemical Resistance: Sponge rubber can exhibit varying degrees of resistance to heat, cold, and chemicals depending on its composition and additives.

Applications:

Seals and Gaskets: Sponge rubber is commonly used for creating seals and gaskets in automotive, aerospace, and industrial applications due to its compressibility and resilience.

Insulation: It is used as insulation material in HVAC systems, appliances, and construction applications due to its thermal and acoustic insulation properties.

Cushioning and Padding: Sponge rubber is used in the manufacture of mattresses, pillows, furniture cushions, and sports equipment to provide comfort and shock absorption.

Packaging: It is also used in packaging materials to protect fragile items during shipping and handling.

Types:

Neoprene Sponge Rubber: Offers good resistance to weathering, ozone, and oil.

EPDM Sponge Rubber: Exhibits excellent resistance to weathering, UV radiation, and ozone.

Nitrile Sponge Rubber: Known for its resistance to oils, fuels, and chemicals.

Silicone Sponge Rubber: Offers wide temperature resistance and is commonly used in extreme temperature environments.

Overall, sponge rubber is a versatile material with a wide range of applications due to its unique properties and structure.